News - March 8, 2024

Green gas: The revolution in the gas industry through biomethane

Article in the AEE Intec "Nachhaltige Technologien" 1|2024 by Andronika Kirov

We are facing a global climate crisis in which targeted measures must be taken to limit global warming to a minimum. Decarbonization is currently one of the most critical energy-use issues against high costs, climate change, new legislation, and natural gas dependency.

Investing in the future: 18 billion euros for biomethane production

In 2022, the European Union imported a record 316 billion euros worth of gas, with more than 90 percent of EU member states heavily dependent on external energy suppliers. This high dependency underlines the crucial importance of renewable gases, which already contribute 21 billion cubic meters. The European Biogas Association's (EBA) investment forecast shows that at least 18 billion euros will be available for biomethane production in the coming years. By 2050, the sector could supply up to 167 billion cubic meters of renewable gas, covering around two-thirds of future gas demand in Europe1. In 2023, the two legislative bodies raised the EU target for the share of energy from renewable sources for 2030 to 42.5 percent, to achieve a share of 45 percent. Renewable energy projects benefit from shortened approval procedures, including biogas and biomethane. In particular, renewable fuels in the transport sector should help to reduce greenhouse gas emissions by 14.5 percent. These targets are guidelines and signposts for a more sustainable, resilient, and secure energy future. A year and a half after adopting the REPowerEU plan, the industry remains committed to achieving the target of 35 billion cubic meters of biomethane by 2030 in response to energy uncertainty and extreme price volatility2.

Biomethane versus natural gas: identical characteristics

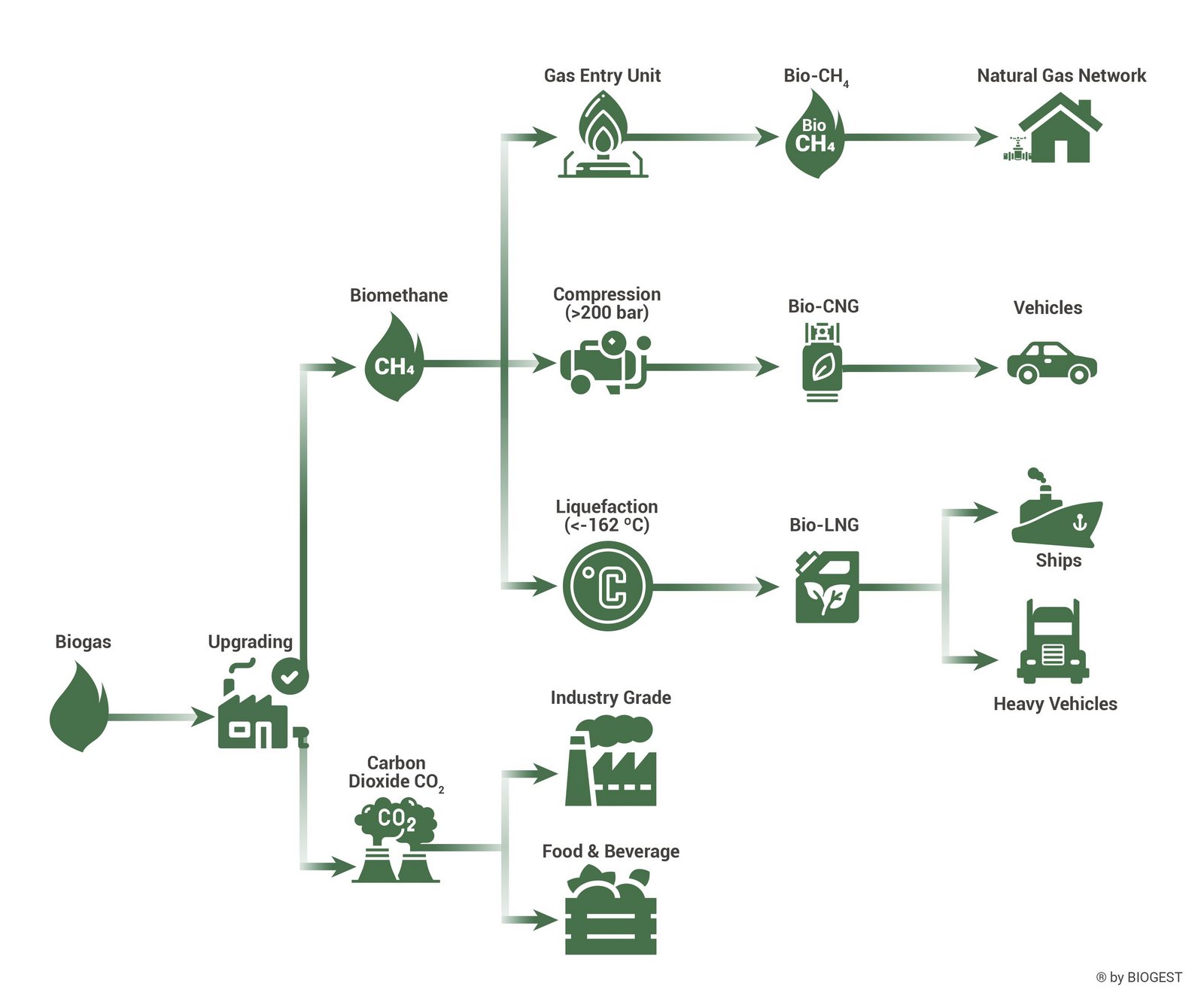

Biogas, produced by the anaerobic fermentation of organic material, is a fuel with a high calorific value that can easily be converted into electricity and heat. It provides regular income as production can take place around the clock. At the same time, it supports decarbonization by recycling organic residues and waste, as the end or fermentation product can be used as fertilizer, thus creating a closed waste or circular economy. Biomethane is a source of methane obtained from purified biogas, which has the same properties as natural gas. Like conventional natural gas, biomethane can be used as a vehicle fuel to support the decarbonization of the transport sector after it has been converted into compressed natural gas (CNG3) or liquefied natural gas (LNG4). The fuel consumption of CNG-powered vehicles is comparable to that of conventional gasoline-powered vehicles and can be used in light to heavy-duty commercial vehicles. LNG is not as widely used as CNG because it is expensive to both produce and store, although its higher density makes LNG a better fuel for heavy-duty vehicles traveling long distances. To best leverage investments in refueling infrastructure, CNG and LNG are best suited for fleet vehicles that return to a base to refuel.

Compared to fossil fuels, biogas and biomethane can save up to 240 percent of GHG emissions of harmful greenhouse gases such as methane, which the uncontrolled fermentation of organic waste and agricultural residues would otherwise release5. Waste and agricultural wastewater are the two primary sources of methane emissions today. Using biogas and biomethane also limits the dependence on mineral fertilizers, as the digestate can be considered fertilizer, not waste. More should be done to promote green fuels through biomethane and the consumption of biogas as a supplement to renewable electricity and to recognize these saved emissions.

Press Contact

BIOGEST®

THE ICON

Gertrude-Froehlich-Sandner-Strasse 2-4

Tower 9, Floor 9

A-1100 Vienna, Austria

E Andronika.Kirovsign: atbiogest.sign: dotat

I www.biogest.at

Biomethane production in Europe

The production costs of biomethane have significant economies of scale, resulting in attractive gas marketing opportunities. The industry has diversified significantly in the last five years, and not only farmers but also international investors and project developers (e.g., from Italy and France) are interested in biomethane production, as long-term purchase agreements with industrial partners or traders offer stability and planning security. Alternatively, a flat-rate tariff that includes methane and certificates enables long-term value creation. The day-ahead gas price6 can be combined with certificates for short-term marketing options. Integrating CO2 into the marketing approach offers an additional source of income, as the by-product (CO2) of biomethane production can be used profitably in many sectors, such as the food and beverage industry. Regional consideration is crucial when exploring demand to identify the best marketing opportunities. These diverse gas marketing options underline the flexibility and profitability of biomethane production in the dynamic energy market. On the largest trading platform for biomethane (ERGaR CoO)7, the volume of biomethane transferred has increased tenfold in just over a year and will amount to 397 GWh in the first quarter of 2023. There is a clear trend among biomethane producers to opt for feedstocks that offer the best GHG savings, i.e., agricultural residues, organic municipal waste, sewage sludge, and industrial waste8.

Why repowering?

The increasing importance of biomethane as an energy source means that existing biogas plants are being converted to produce biomethane (natural gas quality) to meet new market requirements and produce green fuel. The decision for repowering, the conversion and expansion of existing biogas plants, is based on various reasons that consider both economic and technological aspects. Efficiency can be increased through the integration of modern technologies. This not only means an optimized energy yield but also a reduction in operating costs. The availability of raw materials for biogas production can change over time. Adapting to different raw materials is crucial for sustainable and long-term biogas production. By replacing and modernizing outdated plant components, the reliability and performance of the plant can be ensured and contribute to improving operational safety. Using modern technologies and updating safety systems minimizes the risk of malfunctions and promotes reliable and continuous energy production.

Challenges for repowering

The conversion and expansion of biogas plants face a variety of challenges. A changing political and legal framework requires continuous adjustments to overcome uncertainties regarding funding mechanisms and environmental regulations. The availability of suitable substrates is vital, as fluctuations can affect continuous production. Technical adjustments must be seamlessly integrated into operations, while complex approval procedures can cause delays. Due to the increasing use of organic residues and waste materials, pre-treatment and optimally designed agitator and digester technology is crucial, especially with higher dry matter contents and fiber content, to efficiently support the microorganisms in the biogas plant with waste material. The current state of the art in mechanical pre-treatment methods involves shredding units, such as hammer mills or impact shredders, to increase the biomass surface area and simplify mixing. In 2022, over 50 percent of European biomethane plants will use membrane separation technology to refine their biogas. In the last four years, membrane technology has become particularly popular in newly built plants due to its ease of use and comparatively low operating costs. Other technologies, such as pressurized water scrubbing, amine scrubbing, or pressure swing adsorption, can also be economical for very large plants or biogas volume flows9. High initial investments and the need for well-designed infrastructure, including connections and waste transport, pose further financial and organizational challenges. At the same time, the efficient handling of digestate requires adequate storage capacities and fertilizer management strategies. A successful transformation, therefore, requires close cooperation between operators, authorities, and technology providers and flexible adaptation to changing conditions.

"Biogas has developed from a green gas to an all-rounder. Renewable energy can be produced not only in the form of electricity and heat but also in the form of fuel. We see biomethane as a climate-neutral alternative to natural gas, as it can be stored flexibly in terms of time and space. With our biogas and biomethane plants, we not only solve our customers' waste problems but also make a significant contribution to climate protection." - Martin Schlerka, CEO BIOGEST

1EBA Statistical Report 2023 https://www.europeanbiogas.eu/eba-statistical-report-2023/

2EBA Statistical Report 2023 https://www.europeanbiogas.eu/eba-statistical-report-2023/

3Compressed Natural Gas

4Liquified Natural Gas

5https://www.europeanbiogas.eu/wp-content/uploads/2020/04/20200419-Background-paper_final.pdf https://publications.jrc.ec.europa.eu/repository/bitstream/JRC104759/ld1a27215enn.pdf

6The term day-ahead trading refers to the trading of electricity for the following day, which takes place on the EPEX Spot in Paris (spot market of the European Power Exchange), on the EXAA in Vienna or in OTC (over-the-counter) trading via contracts negotiated over the counter. https://www.next-kraftwerke.de/wissen/day-ahead-handel

8EBA Statistical Report 2023 https://www.europeanbiogas.eu/eba-statistical-report-2023/

9EBA Statistical Report 2023, p. 29

Since its foundation in 1988, AEE INTEC has made a significant contribution to the research, development and implementation of sustainable technologies at national, European and international level. True to our motto "Idea to Action", we see ourselves as a bridge builder from basic research projects to the implementation of demonstration plants in real application environments.